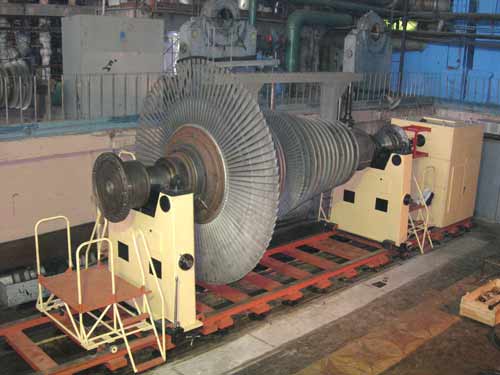

Horizontal soft-bearing balancing machines for steam turbine rotors

Universal soft-bearing balancing machines for highly precise balancing of a steam turbine rotors with masses up to 90 tons.

Universal soft-bearing balancing machines for highly precise balancing of a steam turbine rotors with masses up to 90 tons.

| Standard Specifications | BM-25000 | BM-36000 | BM-65000 | BM-90000 |

| Weight Capacity, tons | 6 - 25 | 7 - 40 | 9 - 65 | 9 - 90 |

| Max. rotor diameter, mm | 4000 | |||

| Distance between the centers of rotor bearing journals, mm | 900 - 7500 | 900 - 8500 | 1500 - 10000 | 1500 - 12000 |

| Shaft journal diameter range, mm | 50 - 500 | 150 - 530 | ||

| Sensitivity, g·mm/kg | 0.1 | 0.4 | 0.2 | |

| Balancing speed, rev/min | 100 - 200 | |||

| Drive motor | AC 35 kW | AC 37 kW | AC 50 kW | AC 50 kW |

| Drive type | End (standard) End + Belt (option) |

End | ||

| Standard base length, mm | 10000 | 12750 | 14000 | 17000 |

| Machine weight, tons | 15 | 16 | 18 | 20 |

| Specifications are for standard machines; modifications are available to meet specific requirements. |

||||

| Customers | ||||

| Machine model | Year | |||

| Mosenergo central repair factory | BM-36000 | 1999 | ||

| Surgut thermal power plant - 1 | BM-36000 | 2001 | ||

| Tumen thermal power plant | BM-36000 | 2001 | ||

| Nizhnovenergo | BM-36000 | 2001 | ||

| Kamenergoremont | BM-36000 | 2001 | ||

| Nizhnevartovsk thermal power plant | BM-36000 BM-90000 |

2002 2009 |

||

| Talimardgan thermal power plant | BM-36000 | 2002 | ||

| Tobolsk thermal power plant | BM-36000 | 2003 | ||

| Konakovo thermal power plant | BM-36000 | 2004 | ||

| Chelyabenergoremont | BM-36000 | 2006 | ||

| Teploenergoservice | BM-36000 | 2006 | ||

| Turbinist | BM-36000 | 2006 | ||

| MAEK-Kazatomprom | BM-36000 | 2006 | ||

| Krasnoyarsk thermal power plant | BM-36000 | 2008 | ||

| West Siberian Metallurgical Industrial Complex | BM-36000 | 2008 | ||

| Energoremont, Ufa | BM-65000 | 2007 | ||

| Verhny Tagil thermal power plant | BM-65000 | 2008 | ||

| Perm thermal power plant | BM-90000 | 2003 | ||

| Surgut thermal power plant - 2 | BM-90000 | 2003 | ||

| Smolensk nuclear power plant | BM-90000 | 2007 | ||

| Kursk nuclear power plant | BM-90000 | 2007 | ||

| St. Petersburg nuclear power plant | BM-90000 BM-36000 |

2007 2008 |

||

| Kashira thermal power plant | BM-90000 | 2008 | ||

| ■ | Highest balance sensitivity - up to 0.1 g·mm/kg in all range |

| ■ | Broad rotor weight range in each machine |

| ■ | Anti-friction bearing work supports eliminate time-consuming alignment procedures. Bearings have a flat, wide-contact surface to carry rotors without damaging journals |

| ■ | Balance at lower and safer speeds |

| ■ | The machine installed without foundations, not required expensive construction of special concrete foundations |

| ■ | Transportable, modular design |

| ■ | Special Complex with computer operating system for turning/grinding operations, which can be used with transportable balancing machine |

| ■ | Geometric tolerance measurement system |

| ■ | Automatic additional turn of a rotor on a required angle |

| ■ | Touch screen balancing computer, with all accessories needed for balancing |

| ■ | The highest quality of manufacturing |

DIAMECH 2000 Ltd.

Vibration Diagnostics & Balancing Machines

Vibration Diagnostics & Balancing Machines